High-Speed Motor

At NS, we utilize high-energy-density rare earth magnets in our high-speed Permanent Magnet Synchronous Motors (PMSMs) to achieve a lightweight, compact design without compromising performance. Through advanced finite element analysis (FEA) software, we optimize every aspect of the motor's design to ensure exceptional efficiency-95% or higher-even at high rotational speeds.

NS brings extensive experience and proprietary design technology to the development of high-speed Permanent Magnet Synchronous Motors (PMSMs), tailored for a wide range of applications-including defense, water treatment, and automotive sectors-as well as specialized environments such as cryogenic conditions.

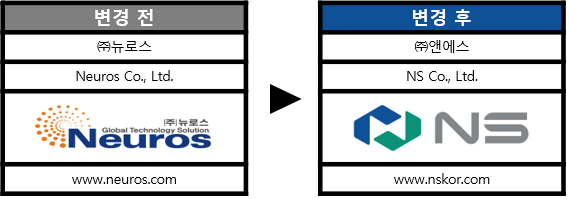

NS High-speed motor development specifications

Electromagnetic analysis using FEA software

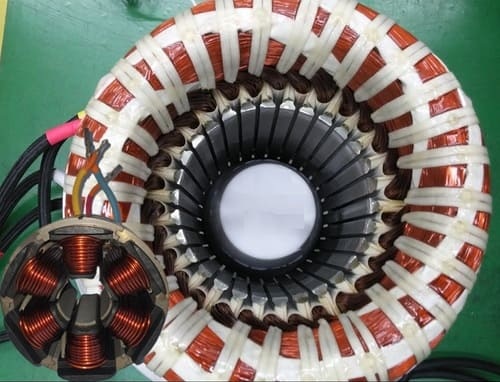

Permanent Magnets and Laminated Stator Cores

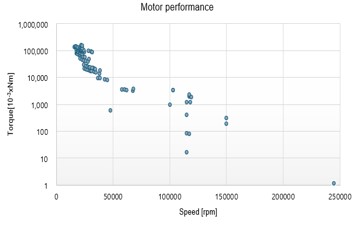

Samarium-Cobalt (Sm-Co) magnets enable operation at over 300°C with minimal magnetic property changes due to temperature variation, ensuring stable performance in high-temperature environments.

To minimize stator core loss at high operation frequencies due to high-speed rotation, we use 0.2t thick low-loss, non-oriented electrical steel sheets produced domestically for high-frequency applications.

Magnet property graph

Integrated and split-type stators

Insulation

The windings use primary materials such as magnet wire, varnish, and insulation paper rated for over 200°C. A vacuum impregnation process is applied, and the system is certified/managed under the 180°C H-class UL insulation system.

Distributed and concentrated winding stator assembly

Insulation Class 180(H) UL COC

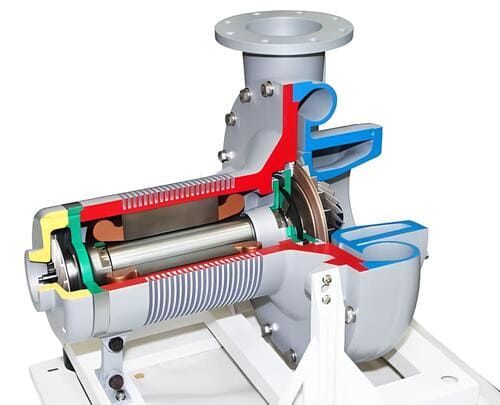

Turbo blower

Using rotors made from special or super alloys and our self-developed air bearings, we further enhance the reliability of high-speed rotors. Based on our unique core layout design for high-speed rotating devices, we have integrated core technologies to enable long-term and stable high-speed operation of impeller-integrated motors.

Rotor assembly

Stator assembly

Turbo blower

High-Speed Inverter

Industrial and Commercial Inverters

NS collaborates with major inverter manufacturers such as KEB, DELTA, VACON, and SEOHO ELECTRIC to provide optimal solutions tailored to customer needs.

High-speed inverters for industrial and commercial applications

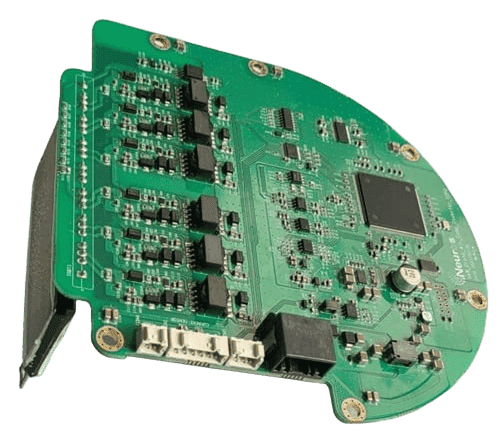

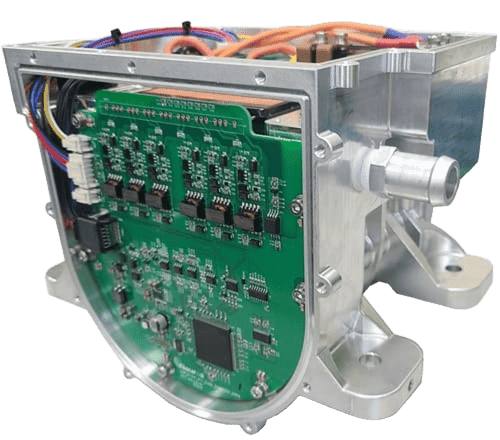

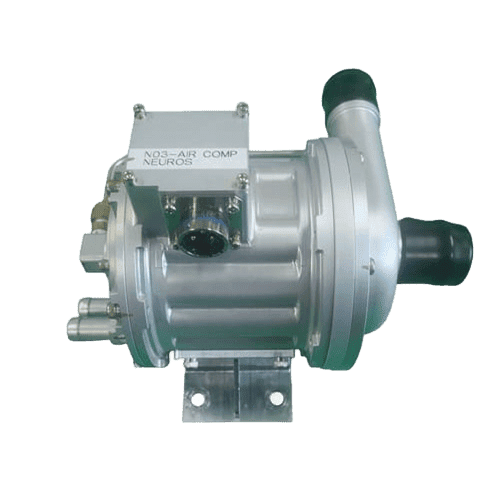

Proprietary Inverter Model - Specialty Vehicles

NS’s proprietary inverter is optimized for PMSM control and developed entirely in-house. Designed as an integrated air compressor and inverter system, it delivers optimal performance for specialty vehicle applications.

High-speed inverter for air compressors used in special-purpose vehicles

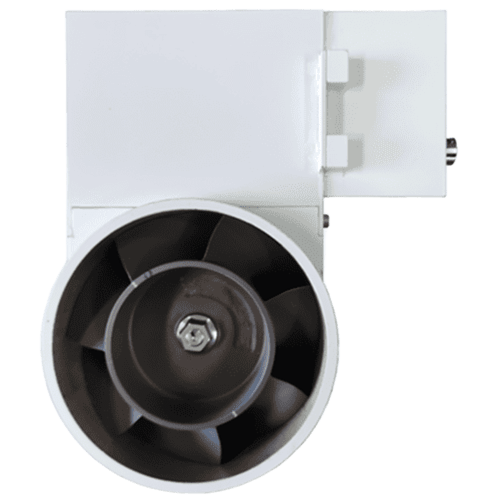

Proprietary Inverter Model - Drones

Designed to be compact and lightweight for space- and weight-constrained environments, with precise and stable control of ultra-high-speed motors (up to 150,000 RPM)

High-speed inverter for air compressors used in drones

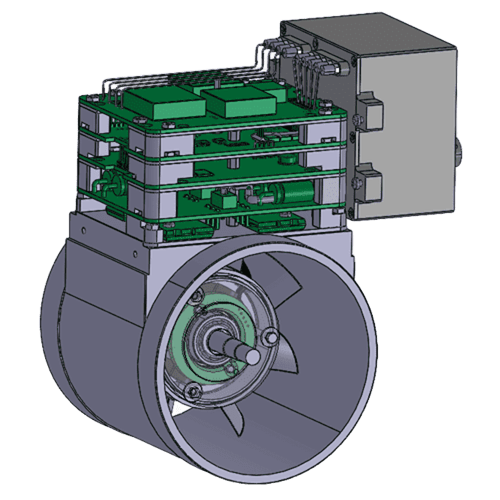

Proprietary Inverter Model - Aerospace Applications

We supply a highly reliable, lightweight inverter developed for the Republic of Korea Army's Light Armed Helicopter (LAH) program.

Inverter for blowers in LAHs