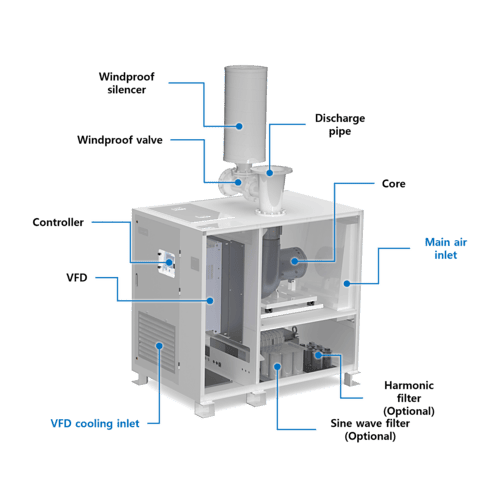

Performance-Optimized Enclosure

The turbo blower enclosure is a protective outer casing engineered to ensure that the performance of the high-speed rotating air compressor and internal electrical components remain uncompromised. At NS, we have leveraged years of research and development, along with cutting-edge technology, to create a turbo blower enclosure that delivers both low loss and low noise performance.

Type

Integrated (standard) / Inlet flange type / Outdoor type / Electrical & inverter split type / Custom type

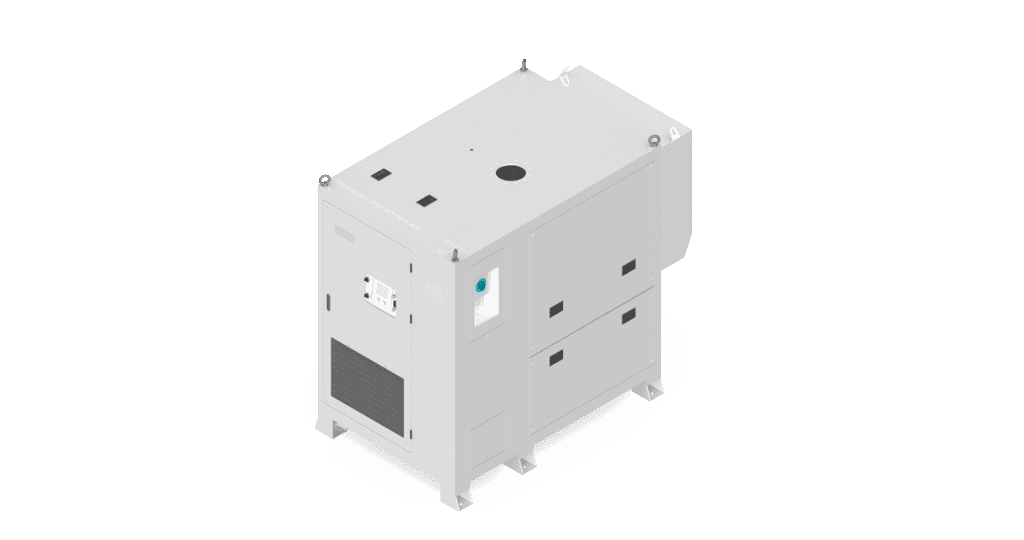

Standard Types

Single core

Dual core

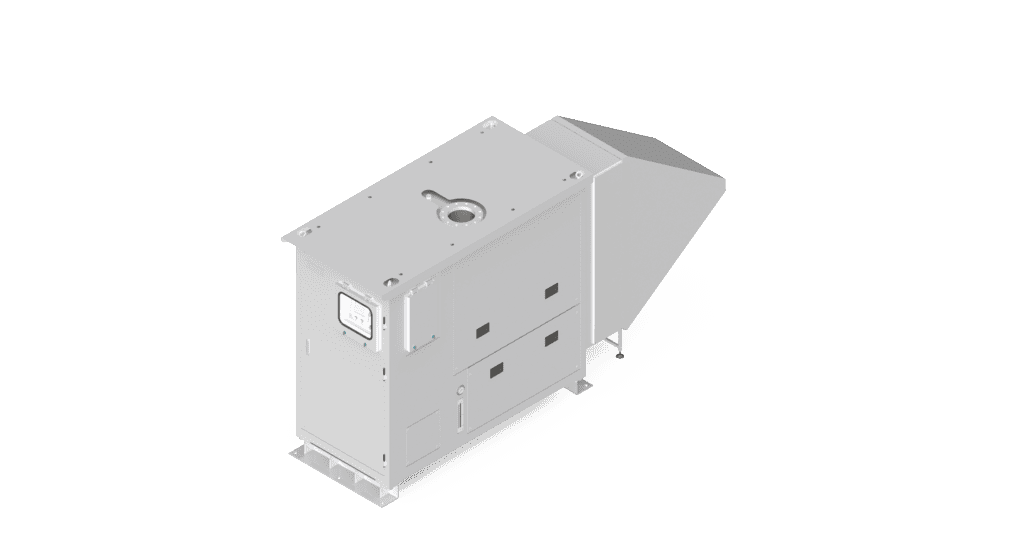

Inlet Flange Type

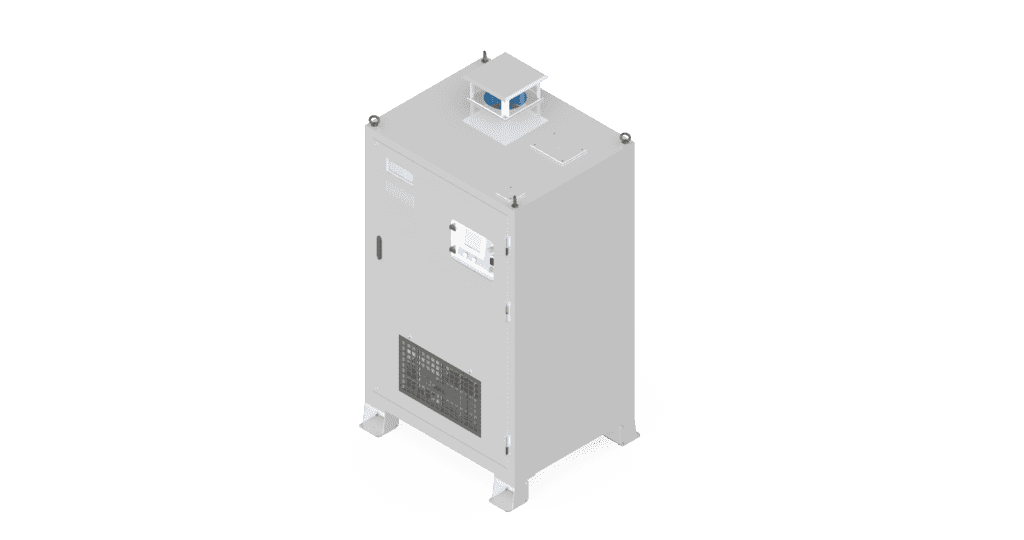

Outdoor Type

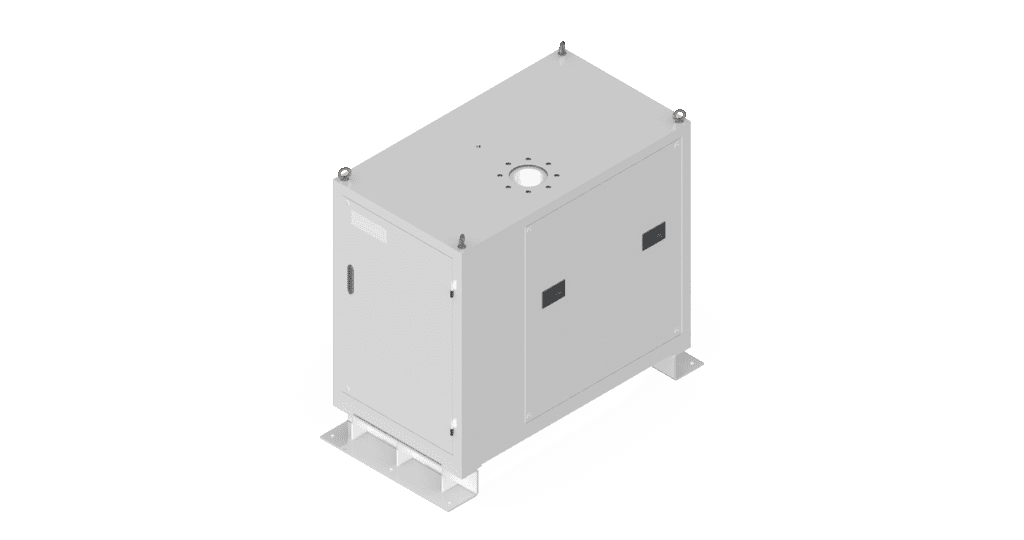

Split Type

Electrical & inverter section

Core section

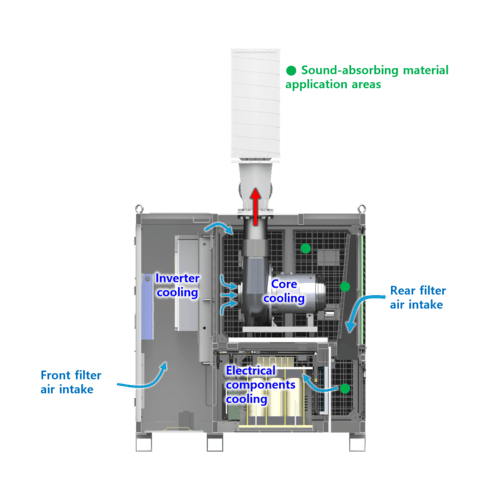

Configuration

Optimized internal airflow and low-noise design

Configuration

Configuration

Automatic Control

PLC

NS products use PLC for control, offering the following advantages:

- Stable control in industrial settings

- Supports various communication protocols for remote operation (Modbus, Profibus, Profinet, Ethernet IP, XGT)

- Supports Analog & Digital I/O for hardwiring type connections

- Easy maintenance

- Real-time monitoring and user-friendly control via HMI

PLC options to meet customer needs

- Allen-Bradley: Compactlogix, Micrologix

- SIEMENS: S7-1200 Series

- LS Electric: XGB, XGT Series

- RS Automation: X8 Series

- Delta: DVP Series

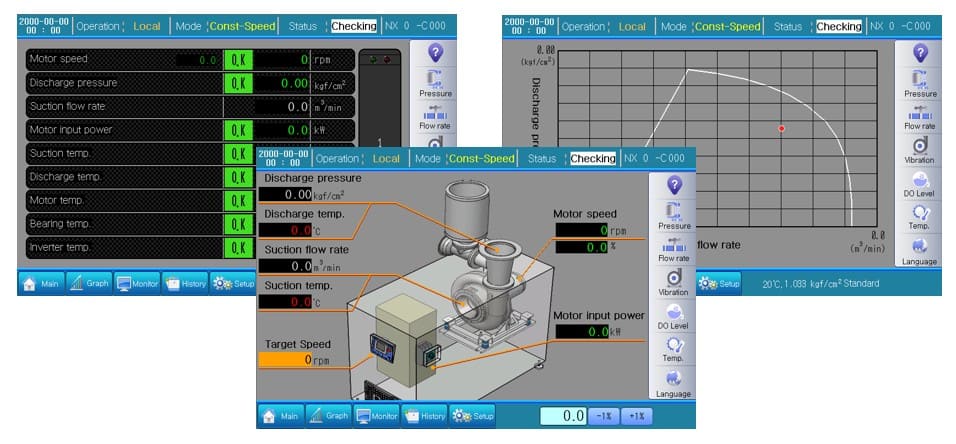

HMI

7-inch wide high-resolution color touchscreen for easy use

Multiple language settings available

- Supported languages: Korean, English, Chinese, Japanese, Russian, Turkish

HMI screen configurations

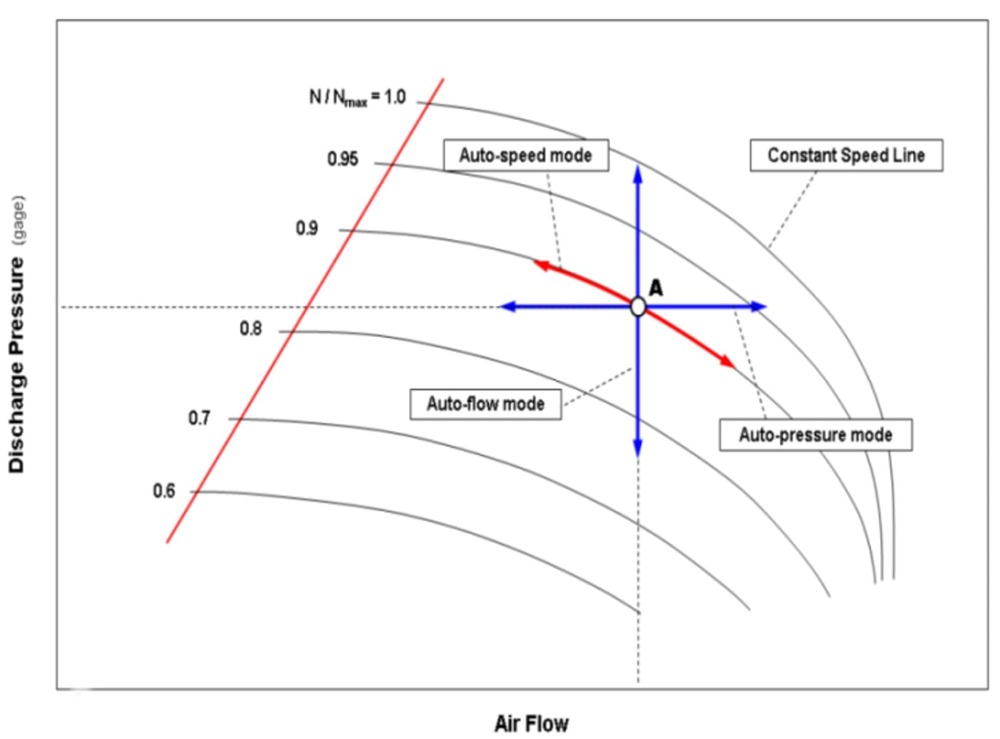

Control Modes

Customers can choose their desired control method:

- Constant Speed Control

- Constant Flow Control

- Constant Pressure Control

- DO Link Control

- Constant Power Control

Master Control Panel (MCP)

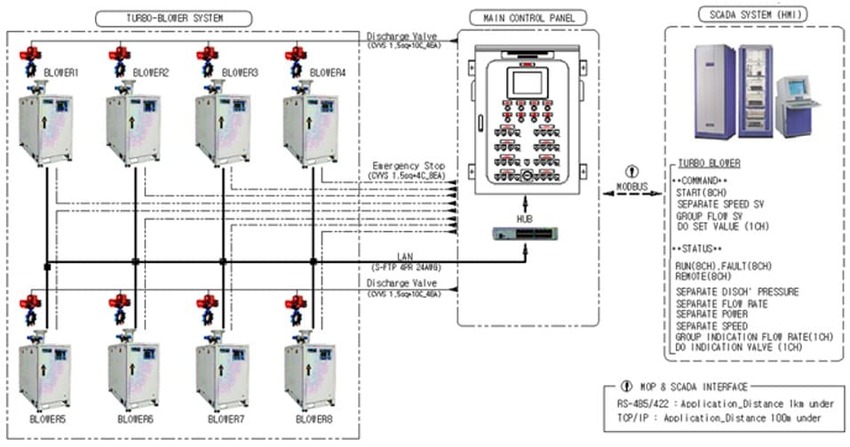

A system designed to control multiple blowers or compressors, enabling individual or integrated operation via SCADA and remote communication

- Integrated control of up to 8 blowers

- Supports LAN communication between MCP and blowers

- Supports Modbus RTU, Modbus TCP, Profibus DP communication between MCP and SCADA

MCP

Integrated control diagram

Electrical Filter

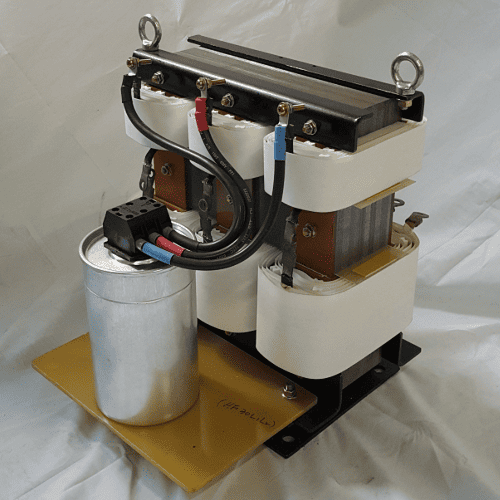

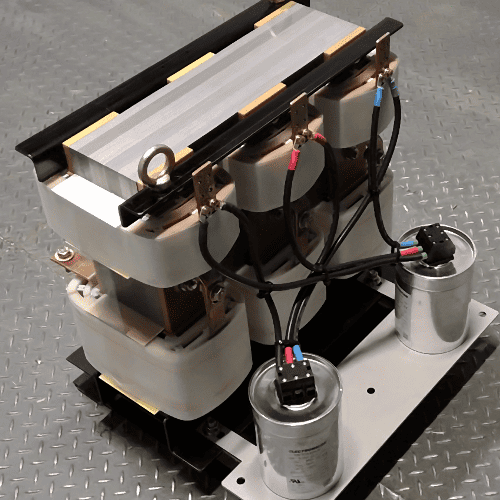

Harmonic Filter

Harmonic filters are installed at the power input side to eliminate harmonics generated by equipment. They are designed per IEEE-519 Standard (THD-V < 5%, THD-I < 8%)

Harmonic filters can be installed inside the blower enclosure (no additional space needed), or externally if required

They are equipped with a dedicated breaker to prevent reactive power flow under no-load conditions

Benefits of harmonic filter installation:

- Improves power quality

- Increases transformer and system capacity

- Prevents equipment malfunction due to harmonics

- Provides noise blocking effect for non-linear loads

- Reduces system losses

Harmonic Filter

External installation type

Sine Wave Filter

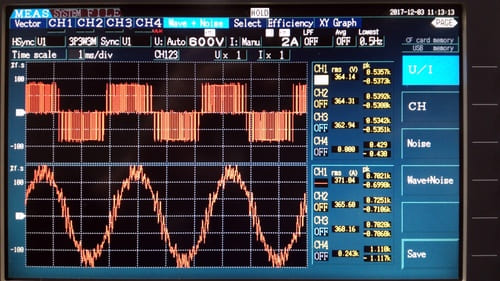

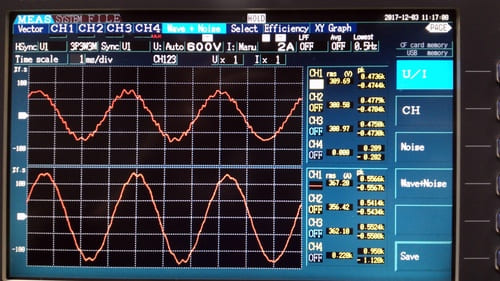

Sine wave filters convert the inverter’s PWM waveform to a sine wave and are installed on the motor input side to protect the motor

NS sine wave filters are designed to operate at motor speeds up to 60,000 RPM

Benefits of sine wave filter installation:

- By applying a sine wave input to the motor, heat generation is reduced and insulation breakdown is prevented.

- Reduced motor noise and electromagnetic interference

- Improved motor efficiency

- Extended motor lifespan

- Enables long-distance transmission of inverter output, allowing the motor and inverter to be installed separately in different locations

Sine wave filter effect

Sine Wave Filter