Oil-free, high-speed air bearings optimized for rotating machinery

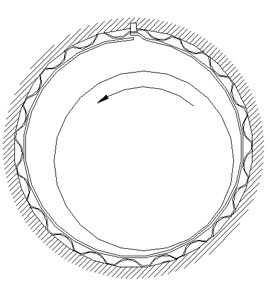

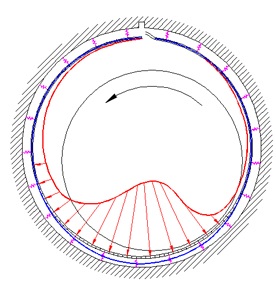

Principle of Operation

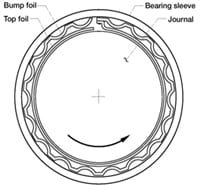

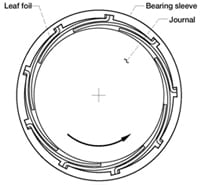

Air bearings are non-contact systems that utilize hydrodynamic pressure generated between high-speed rotating discs and foil structures. NS produces bump-type air bearings, which offer superior load capacity, lower preload requirements, and reduced starting torque compared to multi-leaf designs- all while ensuring outstanding durability.

Hydrodynamic Pressure Generation

Bump-Type Foil Bearing

Leaf-Type Foil Bearing

Features

NS develops and manufactures high-performance air bearings based on extensive design and mass production experience.

Our air bearings are applied in ACMs (Air Cycle Machines) and ECS (Environmental Control Systems) for aircraft, as well as in hydrogen FCEV air compressors, proving their reliability in real-world operations.

- 100% Oil-Free, non-contact operation

- The bearing and shaft operate without contact, providing stable performance at high speeds without external lubrication.

- Simple structure, easy maintenance

- No lubrication system is required, leading to simple system structure and minimal maintenance

- Oustanding durability and themal stability

- Withstands repeated on/off cycles without performance degradation and operates reliably across a wide temperature range.

- Low noise·low vibration, eco-friendly technology

- Enables non-contact, low-noise operation, and provides an eco-friendly working environment with approximately 1/5th the vibration level compared to traditional blowers

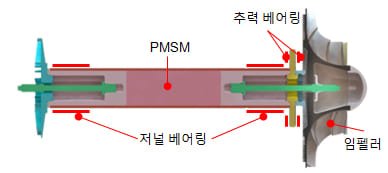

Configuration and Function

- Two bump-type journal bearings + one set of bump-type thrust bearings

- Journal bearings: rotor weight, unbalanced mass load, and rotor instability → Impact on operability

- Thrust Bearings: axial load, blade clearance adjustment, and power loss → Impact on performance

Bump-type journal bearing

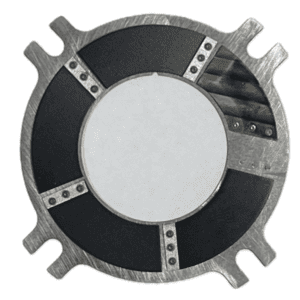

Welded-type thrust bearing

Integral-type thrust bearing

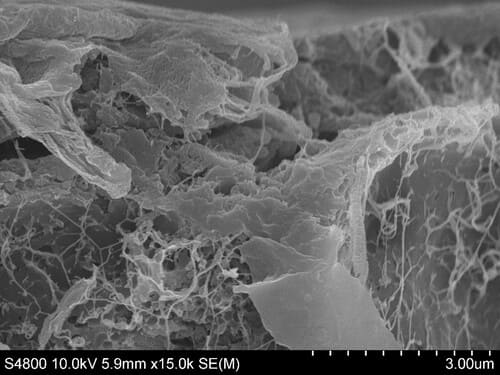

Surface Coating

Teflon coating in foil air bearings plays a key role in reducing friction and wear between the rotor and bearing during startup and shutdown. Optimized surface roughness reduces initial friction for fast and stable lift-off, enhancing durability and performance.

SEM image coating cross-section (3,000x)

SEM image coating cross-section (15,000x)

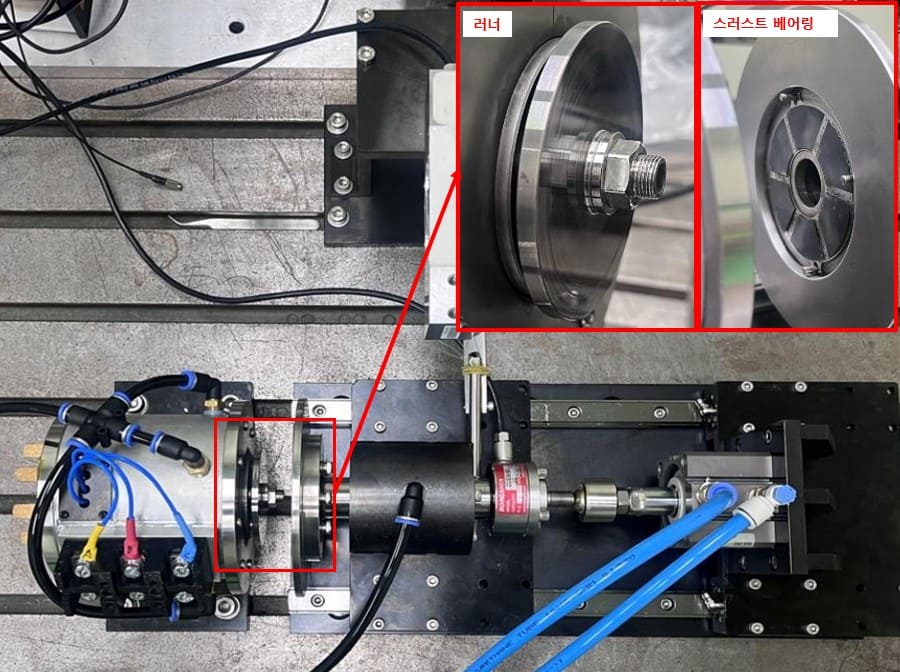

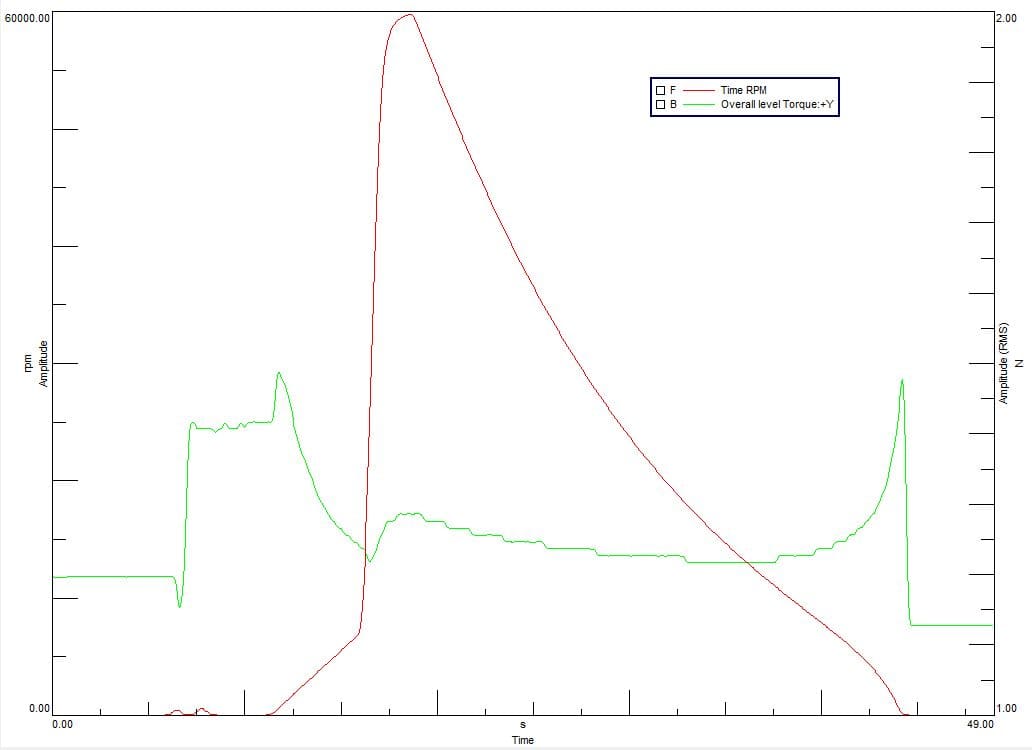

Evaluation

NS designs, manufactures, and evaluates air bearings to ensure performance and reliability of turbomachinery.

We conduct performance evaluations under high-speed/high-load operating conditions to ensure optimal quality of our turbomachinery.

Thrust bearing lift-off evaluation