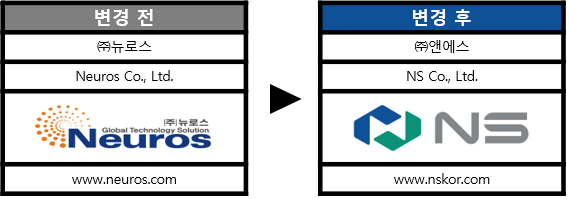

Vibration Testing

Vibration testing using shakers alllows for verification of seismic resistance and structural stability under various operating conditions and environments. Accelerated vibration testing is conducted to simulate actual operating conditions, improving reliability and product lifespan

- Measurement of natural frequency and vibration modes

- In-vehicle mode vibration profile testing

- High Cycle Fatigue (HCF, High Cycle Fatigue)

- Verification of structure vibration durability and fatigue limits

- Vibration characteristic analysis of rotating components such as vanes and blades

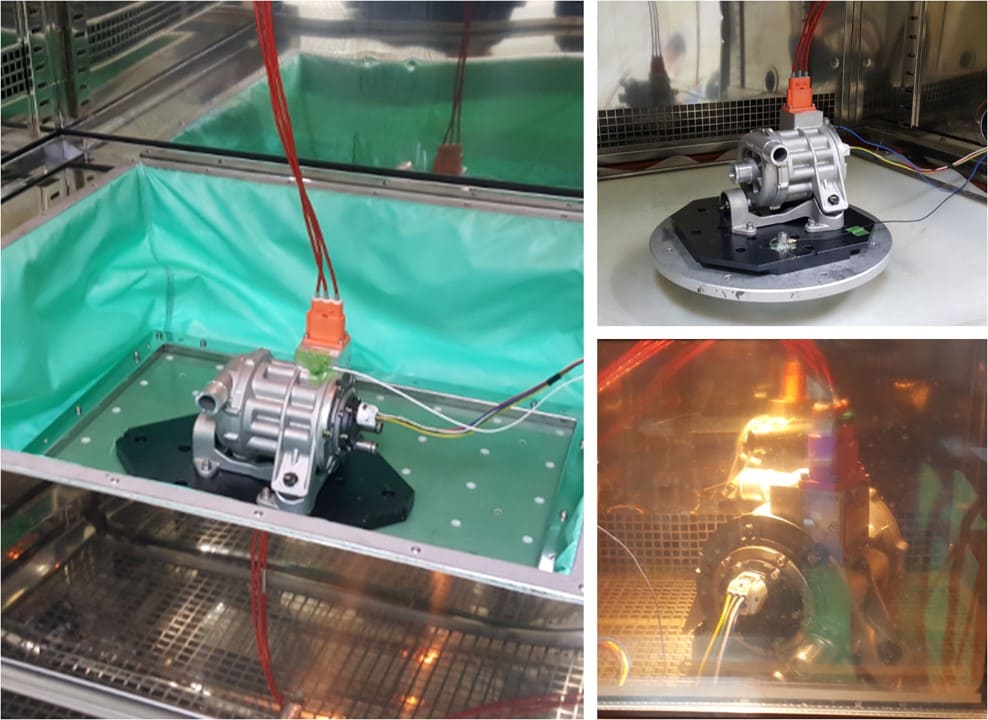

Combined Environmental Testing

Through the simultaneous application of temperature cycling and mechanical vibration during combined environmental testing, we can assess environmental resistance and durability under extreme operational conditions. Reliability is verified under thermal/mechanical combined stress, simulating actual usage environments with repeated high- and low-temperature conditions.

Applicable to: parts exposed to repetitive vibration environments, such as automobiles, aircraft, railways, and ships

- Resistance to combined temperature/vibration stress

- Identification of resonant frequency changes due to thermal expansion

- Durability verification via simulation of actual operating conditions