Spin Test (Overspeed Test)

Strict spin tests are conducted on rotating products to ensure the highest level of structural integrity and reliability.

Spin testing simulates the extreme centrifugal forces experienced during high-speed rotation. This process strictly verifies the material’s centrifugal strength, ensuring it can withstand such stress without damage or deformation. It also helps identify any microstructural defects or potential risks before the product reaches our customers, ensuring safe and reliable performance.

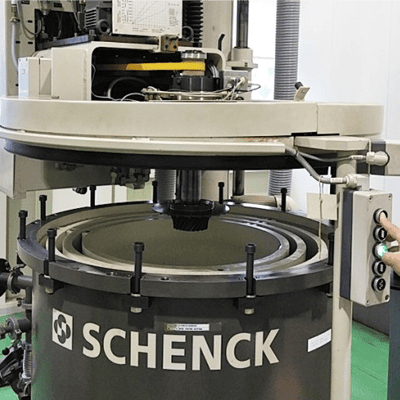

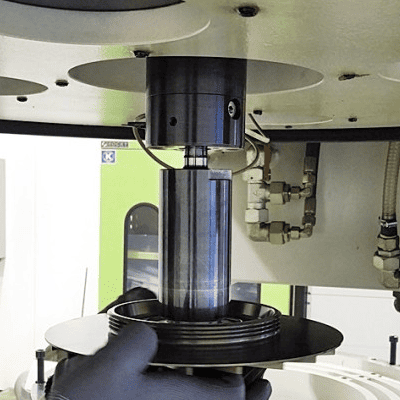

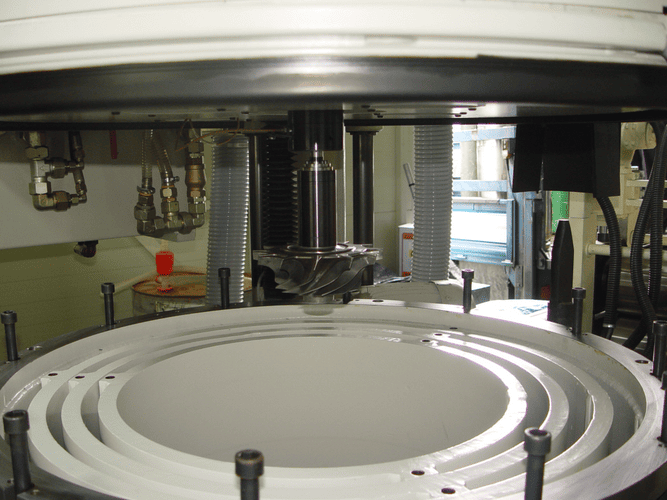

Testing Equipment

| Spin Test Equipment Specifications | ||

|---|---|---|

| Rotor Diameter | mm | 500 |

| Rotor Length | mm | 515 |

| Rotor Weight / Speed | kg / RPM | 50 / 125,000 |

| kg / RPM | 10 / 200,000 | |

Test Procedure

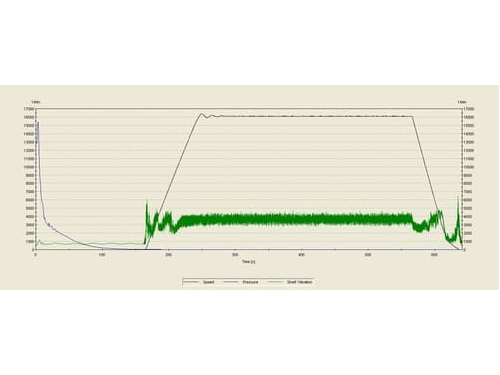

The spin test begins by precisely mounting the rotor onto the test equipment. The rotation speed is gradually increased in controlled stages.

During overspeed conditions - beyond the product’s rated speed - vibration, noise, and other anomalies are closely monitored in real time. After testing, the rotor undergoes a thorough inspection to verify its structural integrity and confirm that it meets design specifications.

Test Application

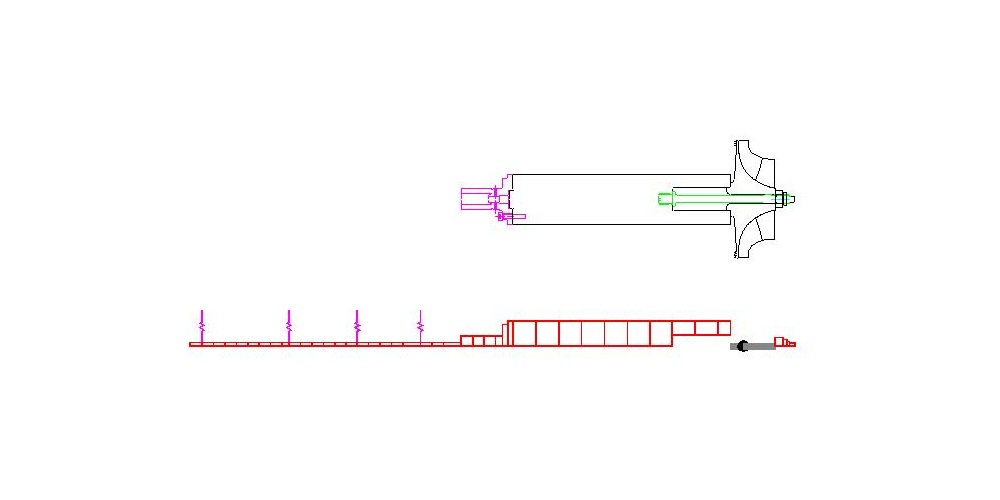

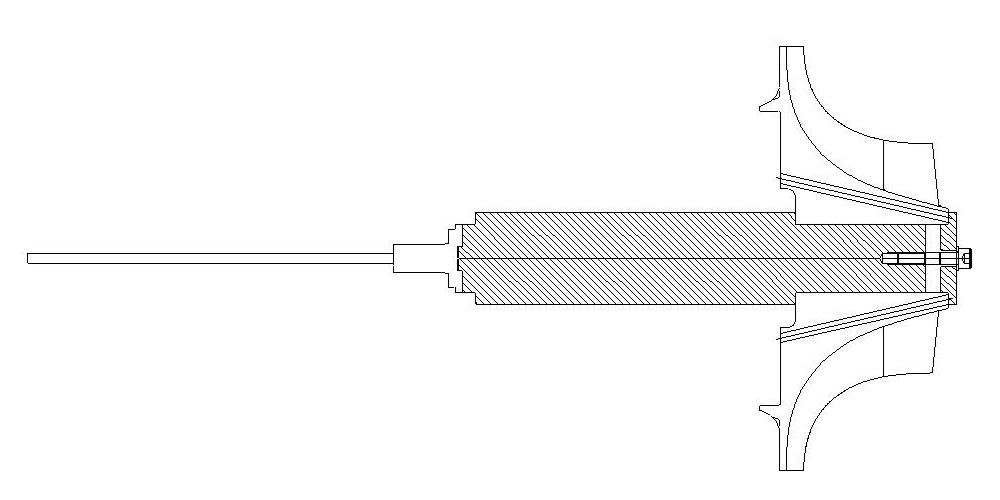

Arbor and Dummy

Design

Arbor and Dummy

Fabrication

Dummy

Spin Test

Final Rotor

Spin Test

- Arbor, Dummy Design

- Balancing, Runout

- Spin Test