Balancing

After a rotor is manufactured, if mass is not evenly distributed

around the center axis, mass imbalance will occur at specific

points

When rotating in this state, centrifugal force causes vibration,

negatively affecting rotor performance and lifespan

NS professionally performs 'precision balancing' to adjust mass imbalance according to specified standards.

Purpose

• Balancing is an essential process in the manufacturing of all rotating machinery

• Persistent imbalance can cause product wear or damage due

to vibration and consequently reduce product lifespan

• It may also increase noise levels, leading to operator fatigue

and decreased productivity and quality

• Balancing enhances product quality and reliability at minimal time and cost

Standards and Grades

Balancing is more than a simple adjustment- it must be performed under standardized criteria for stable operation in real conditions.

The following factors must be comprehensively considered:

- Types of rotors

- Shape and structural characteristics

- Rotational speed (RPM)

- Weight and size

- Installation location and operating environment

- Product's intended application

Balancing Grades

| Grade(G) | Application Examples | Description |

|---|---|---|

| G 4000 | Very low-speed rotors (e.g. large drums for lathes) | Large imbalance allowed |

| G 160 | General industrial fans, pumps, etc. | Standard industrial rotors |

| G 6.3 | High-speed motors, turbines, machine shafts, etc. | General precision machinery level |

| G 2.5 | High-speed grinders, precision motors, etc. | High-precision rotors |

| G 1.0 or below | Aircraft components, precision measuring instruments, etc. | Ultra-precision rotors, only minimal imbalance allowed |

- The lower the G-grade value, the higher the required precision. NS provides high-precision balancing services from G 6.3 down to G 1.0 or lower, according to customer specifications

Applicable Standards

NS performs balancing based on the following domestic and international standards:

- ISO 21940 Series - Mechanical Vibration and Balance Quality Standards for Rotating Bodies

- KS B 21940 - Korean Standard based on ISO 21940

- Other customized standards as required by the customer

Testing Equipment

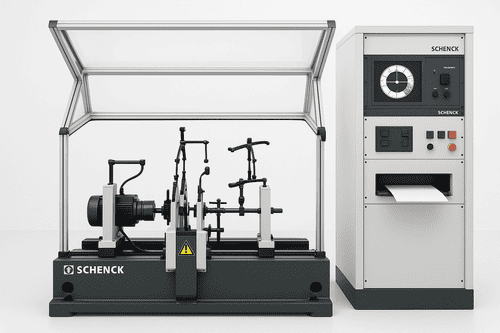

HM2BU-L

General Equipment

- Model: HM2BU-L

- Manufacturer: SCHENCK

Equipment Specifications

- Max rotor weight range: ~50kg

- Max rotor shaft length: 1330mm

- Min rotor shaft length: 50mm

- Max rotor diameter: Ø740mm

- Balancing accuracy: 0.1g∙mm

ZB 5_B10

General Equipment

- Model: ZB 5 TC/GV

- Manufacturer: CEMB – HOFMANN

Equipment Specifications

- Max rotor weight range: 0.05 ~ 10kg

- Max rotor shaft length: 420mm

- Min rotor shaft length: 10mm

- Max rotor diameter: Ø260mm

- Balancing accuracy: 0.08g∙mm