Industrial Turbomachinery

NS delivers custom solutions across various industrial turbomachinery products.

We guarantee industry-leading performance, exceptional reliability, and the highest energy savings.

Why are businesses choosing NS Turbomachinery?

THE HIGHEST PERFORMANCE

Our turbo blowers combine high-efficiency impellers, PMSMs (Permanent Magnet Synchronous Motors), and VFDs (Variable Frequency Drives) for top-tier performance.

- Achieving up to 75% overall efficiency, our turbo blowers can help save 30-50% more energy compared to coovnentional blowers, recoouping investment costs within an average of 2 years

- NS-designed PMSMs are optimized for high-speed operation, achieving over 95% efficiency and direct drive without gears

- With a high-efficiency VFD, the speed of the PMSM is precisely controlled, enabling a wide flow control range of 40–100%. This ensures optimal operating performance while minimizing energy waste

EXCELLENT RELIABILITY

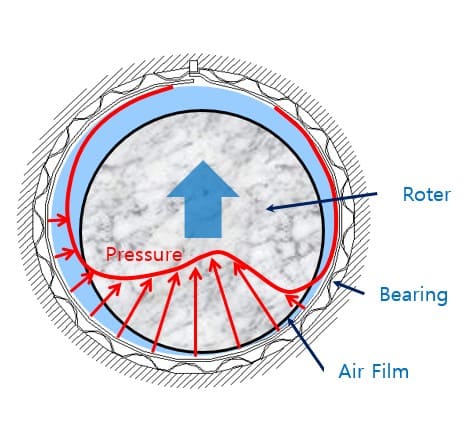

Developed from expertise in turbojet engine technology, NS’s air bearings are now trusted in hydrogen vehicle compressors, aircraft ACM/ECS systems, and other demanding applications where their reliability has been proven. Combined with proprietary cooling and control systems, we ensures exceptional reliability for our customers.

Certified by UL (Underwriters Laboratories Inc.,) and CE (Conformité Européenne), our machines meet international safety and performance standards.

- Proprietary air bearing technology enables quiet, vibration-free, completely oil-free air compression.

- Our advanced cooling system, inspired by aviation technology, utilizes only intake air for high-efficiency cooling, eliminating heat discharge and maintaining a comfortable ambient environment

- An integrated self-diagnosis and alarm system proactively detects surges, faults, and warnings, ensuring stable and uninterrupted operation

- NS holds certifications including ISO9001, IATF16949, UL, and CE. Recognized for high-efficiency systems, we set the standard for quality

ECONOMICAL LIFE CYCLE COST

NS industrial turbo machinery delivers maximum energy cost savings and minimal maintenance expenses, providing increased profitability for our customers.

- Our products reduce lifecycle costs (LCC) significantly when compared to conventional blowers, offering fast ROI and high customer value

- Regular maintenance is limited to cleaning and replacing the intake filter. The dual-filter system prevents foreign material ingress and optimizes performance

Turbo Blower

NX Series

NX Series turbo blowers deliver user-focused, eco-friendly performance by integrating high-efficiency impellers, air bearings, and permanent magnet synchronous motors (PMSMs).

- Applications: Water treatment, pneumatic conveying, air knife, etc.

- Bearings : Foil Air Bearings

- Motor Power: 30 - 1,000HP

- Inlet Flow Rate: 9 - 674m3/min

- Discharge Pressure: 0.3 - 1.0kgf/cm2(g)

NXM Series

NXM turbo blowers combine high-efficiency impellers with advanced magnetic bearings to deliver industry-leading performance and reliability. Their non-contact, oil-free design significantly reduces maintenance while ensuring clean, sustainable, and high-performance operation across a wide range of industrial applications.

- Applications: Water treatment, pneumatic conveying, air knife, etc.

- Bearing: Magnetic Bearing

- Motor Power: 150 - 350kW

- Inlet Flow Rate: 80 - 290m3/min

- Discharge Pressure: 0.7 - 1.1kgf/cm2(g)

Turbo Compressor

NC Series

NC turbo compressors are engineered to deliver precise, optimal pressure with minimal loss- achieving superior energy efficiency and reliability under conditions that challenge conventional high-pressure compressors. They are the ideal solution for enhancing productivity and ensuring stable, long-term operation in demanding industrial environments.

- Applications: Water treatment, pneumatic conveying, blending, etc.

- Bearings : Foil Air Bearings

- Motor Power: 100 - 600HP

- Inlet Flow Rate: 9 - 674m3/min

- Discharge Pressure : 1.1 - 2.0 kgf/cm2(g)

Key Features

1. Industry-leading, proven technology

NS’s air bearings are non-contact systems that utilize hydrodynamic pressure, automatically generated between a high-speed rotating disk and a foil structure. Backed by more than 60 domestic and international patents, our air bearings have been rigorously validated through extensive on/off testing-achieving up to 1 million cycles for mobility applications and 100,000 cycles for industrial use.

2. Exceptional energy savings with high-efficiency impellers and motors

Leveraging years of experience in axial and centrifugal compressor development for both aerospace and industrial applications, NS has engineered high-efficiency impellers with optimized aerodynamic design. Our proprietary Permanent Magnet Synchronous Motor (PMSM) is designed for high-speed operation with minimal current loss, delivering over 95% efficiency and power factor for superior performance.

3. Easy Installation and Operation with Plug & Play Package System

Developed using NS’s advanced R&D capabilities and cutting-edge technologies, our systems are engineered to minimize noise and vibration while preventing interference with high-speed compressors and electronic components. The compact design enables quick and easy installation, even in confined spaces, and allows immediate operation with just a simple power connection.