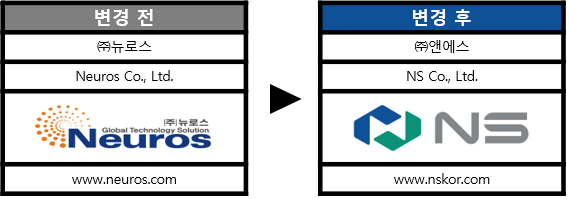

Micro-Filtration Membrane Porometer

Based on the capillary flow (bubble point) method, this instrument automatically measures the pore size distribution of various microfiltration materials, including filter paper, carbon paper, porous ceramics, sintered metals, polymer membranes, woven and non-woven fabrics, and glass filters. With a measurement range of 0.01–100 μm, it accurately identifies effective pore throat size and diameter while avoiding interference from blind pores

- Testing pressure: 0~3.5 Mpa

- Testing flowrate: 0~200 L/min.

Key Measurement Items

| Feature | Description |

|---|---|

| Maximum pore size | Largest pore through which gas first passes |

| Mean flow pore size | Pore size at which 50% of total flow occurs |

| Minimum pore size | Pressure at which gas begins to pass through all pores |

| Pore size distribution | Pore size distribution curve |

| Permeability | Gas flow rate per unit area |

Main Applications

| Field | Use Case |

|---|---|

| Membrane Manufacturing | Quality control for UF, MF, and NF membranes |

| Precision Filtration | Development of pharmaceutical and semiconductor filters |

| Ceramic Filters | High-temperature performance evaluation of porous materials |

| Textile Industry | Analysis of pore characteristics in functional textile fibers |

| Fuel Cells/Batteries | Evaluation of gas permeation in separation membranes |

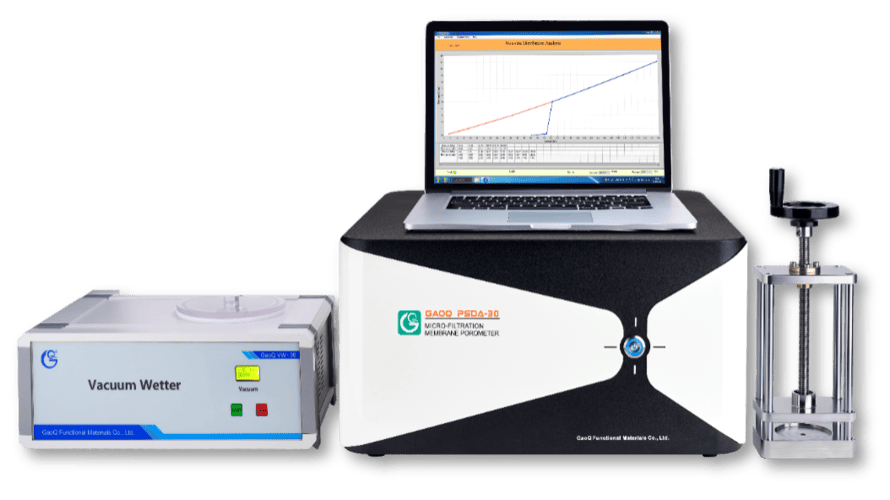

Filter Integrity Tester

Suitable for all types of filter elements—tubular, flat, spiral, hollow fiber, capsule, pleated—and complete filtration systems

Key Measurement Items

| Feature | Description |

|---|---|

| Bubble Point | Pressure at which the largest pore opens |

| Diffusion Rate | Gas flow rate through a wetted filter |

| Pressure Decay | Verification of pressure retention in a sealed state |

| Flow Rate | Measurement of gas flow under dry conditions |

Main Applications

| Feature | Use Case |

|---|---|

| Pharmaceutical/Bio | Validation of sterile processes; applicable to vaccine and protein production |

| Food & Beverage | Sterilization process verification for products such as beer, bottled water, and dairy |

| Semiconductor/Chemical | High-purity filter validation for DI water and process gas filtration |

Membrane Pure Water Fluxmeter

Equipped with a temperature control and purification system. Testing is supported under both positive pressure (0–1 MPa) and negative pressure (-50 kPa to 1 MPa)

Key Measurement Items

| Feature | Description |

|---|---|

| Flux | Flow rate per unit area per unit time |

| Permeability | Flow rate normalized by pressure (Flux / Pressure) |

| Transmembrane Pressure | Pressure difference across the membrane |

| Rejection/Retention | Solute removal efficiency |

Main Applications

| Feature | Use Case |

|---|---|

| R&D | Performance verification of new membranes |

| Filter Manufacturers | Quality control |

| Water Purification/Ultrapure Water Systems | Filter performance monitoring |

| Pharmaceutical/Food & Beverage | Comparison of flow rate before and after filtration |

| Ceramic/Metal Filters | Water permeability testing and comparison before and after cleaning |