Stainless Steel Membranes

- FCC (Fluid Catalytic Cracking) oil slurry is a residual oil generated from catalytic cracking units in refineries. It has high density and viscosity and contains catalyst powder, heavy metals, and residual carbon

- These solid particles can cause equipment wear and clogging, significantly reducing the usability and economic value of the oil slurry

- Oil slurry is a critical fuel component in naval vessels and warships

- Since 2020, the International Maritime Organization (IMO) has enforced regulations lowering sulfur content in marine fuels from 3.5 wt% (2012) to 0.5 wt%, increasing demand for low-sulfur oil slurry

Main Applications

| Field | Use Case |

|---|---|

| Refining/Petrochemical | High-temperature, high-pressure catalytic filtration, FCC slurry purification |

| Pharmaceutical/Bio | Sterile filters, virus removal filters |

| Semiconductors | Chemical filtration, ultrapure water treatment |

| Food & Beverage | Fine particle removal, beer/wine filtration |

| Gas Separation | High-purity gas filtration, hydrogen purification |

| Metal 3D Printing | Powder recovery filters, powder bed management |

| Fuel Cells/Batteries | Membrane support layers, electrode substrates |

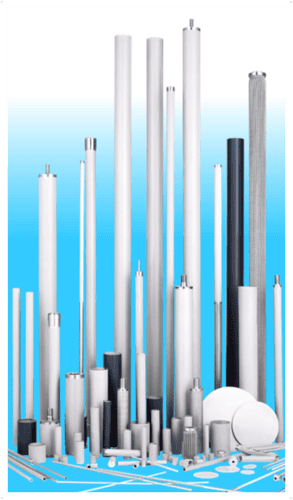

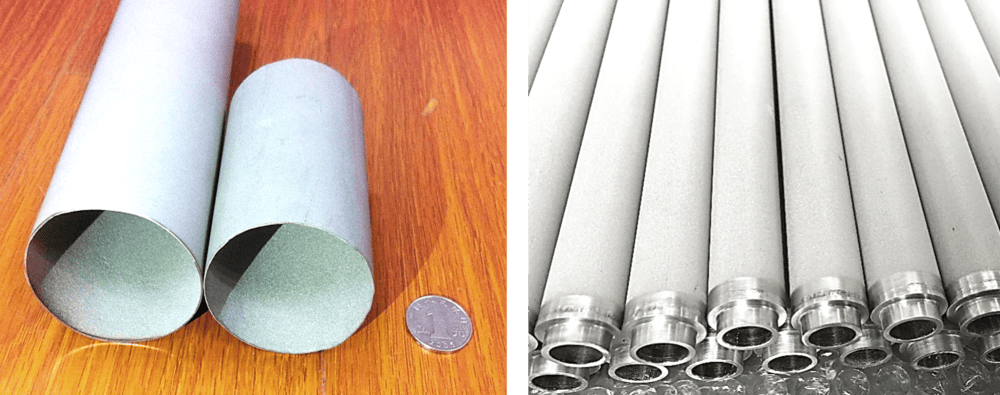

Cylindrical Stainless Steel Filters

Available in diameters ranging from 3–15 mm, offering a large surface area ideal for a variety of microsystems. Cluster filter configurations can be used to enhance filtration efficiency. Constructed from durable stainless steel and can be formed into custom shapes

- Commonly used for solid-liquid separation in refinery processes involving slurry oil or other high-viscosity fluids

- Effectively removes solid particles such as catalysts and sludge from oil

- Multiple filters can be installed as clusters to support continuous operation—one side filters while the other undergoes cleaning

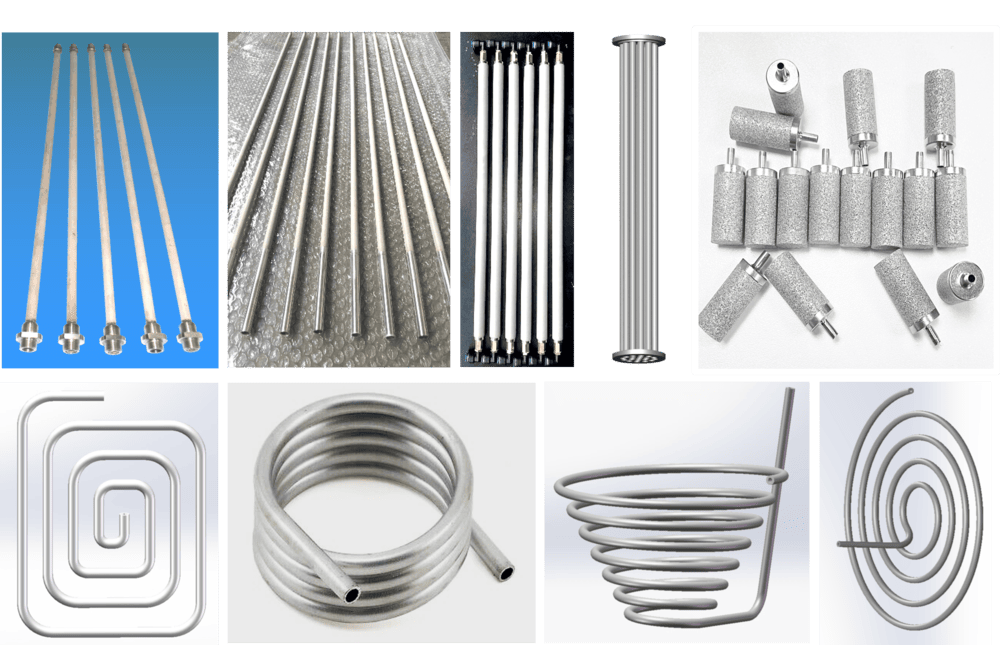

Thin-Wall Stainless Steel Filters

The lightweight structure of the filter offers low diffusion resistance and high filtration efficiency, while also providing excellent resistance to fouling. It surpasses metal meshes and wire or woven mats in terms of filtration precision and is especially effective in dust-laden or high-load environments

Features & Advantages

| Feature | Description |

|---|---|

| High-Precision Filtration | Removes particles ranging from micron to sub-micron scale |

| Heat/Pressure Resistance | Withstands high-temperature and high-pressure environments without deformation |

| Corrosion Resistance | Resists damage from chemicals and acidic fluids |

| Reusability | Can be backflushed and reused multiple times |

| Thin-Wall Structure | Enables rapid fluid flow and maintains a low pressure drop |

Main Applications

| Field | Use Case |

|---|---|

| Refining/Petrochemical | FCC slurry oil treatment, catalyst recovery, removal of oil-borne solids |

| Pharmaceutical | Purification and sterilization of high-purity raw materials |

| Semiconductors | Filtration of chemicals and DI water |

| Food & Beverage | Ingredient purification and fine filtration |

| Water Treatment | Precision filtration, pre-treatment for reverse osmosis | |