Palladium Membranes

A palladium membrane is a high-performance metal membrane engineered to selectively permit hydrogen gas to permeate through

Hydrogen molecules diffuse into the palladium, become ionized, and are released back into a gaseous state - enabling high-purity hydrogen separation

Operating Principle

- Feed gas containing small molecules is introduced to one side of the palladium membrane

- Hydrogen molecules are ionized on the palladium surface and diffuse through the metal

- Inside the membrane, hydrogen ions recombine into gaseous hydrogen and are discharged on the opposite side

- The membrane selectively blocks all other gases, enabling hydrogen-only permeation

Key Features of Palladium Membranes

| Features | Description |

|---|---|

| Hydrogen Selectivity | Palladium selectively permeates only hydrogen, blocking other gases |

| Heat Resistance | Maintains excellent performance even in high-temperature environments, up to 300°C to 500°C |

| Chemical Resistance | Exhibits outstanding chemical resistance, even under oxidizing conditions |

| Hydrogen Permeability | Offers fast and efficient hydrogen diffusion properties |

| High-Purity Hydrogen Purification | Delivers ultra-high purity hydrogen through precise separation mechanisms |

Main Applications

| Field | Use Case |

|---|---|

| Hydrogen Purification | High-purity separation of hydrogen for industrial and laboratory gases |

| Fuel Cells | Purification systems for ultra-pure hydrogen supply |

| Semiconductors | Used in processes requiring extremely high hydrogen purity |

| Petrochemicals | Hydrogen separation during the FCC (Fluid Catalytic Cracking) process |

| Chemical/Bio | Hydrogen purification for analytical and precision manufacturing environments |

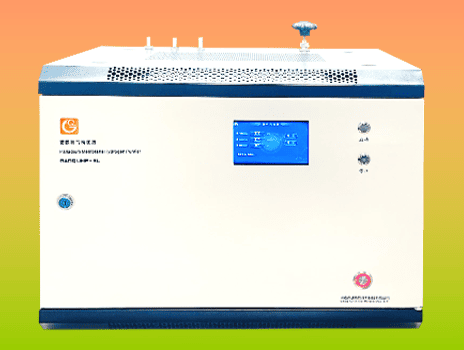

Hydrogen Purifier

- Pure H2 : ≥4N, Highly pure H2 : ≥5N, Ultra pure H2 : ≥6N, Ultra high H2 : ≥7N

- Raw hydrogen

- Catalytic Reforming (coal, natural gas, methanol, ethanol, dimethyl ether, gasoline, etc.)

- Chemical Decomposition (ammonia, ammonia borane, sodium borohydride, hydrides, formic acid, aluminum + base, silicon + base, etc.)

- Electrolyzed Water (alkaline solution, pure water)

- Bio-Hydrogen Production (microbial fermentation, photosynthetic algae, biomass gasification, etc.)

- Various By-product Hydrogen Sources (chlor-alkali, refining, petrochemical, coke, coal chemical, waste treatment, etc.)

- H₂ Capacity: Varies depending on membrane surface area and operating conditions

- H₂ production: 0.05~1000 m3/h

- H₂ purity: 99.999~99.9999999%

- Feed pressure: 0.5~50 bar

Hydrogen Purifier for CVD

CVD hydrogen purifiers based on palladium membranes deliver hydrogen with 8N–12N purity, ideal for CVD processes in semiconductor chip and TFT-LCD production

CVD (Chemical Vapor Deposition) - a technique used to deposit solid thin films on substrates via chemical reactions in high-temperature environments

Widely used in MPCVD processes for the production of high-quality synthetic diamonds with enhanced clarity and color

(Especially suited for semiconductor and diamond manufacturing applications)

MPCVD (Microwave Plasma CVD) - a technology primarily used for diamond thin film growth and nanomaterial synthesis

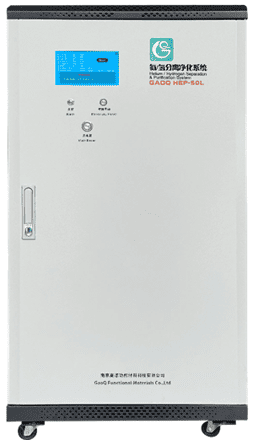

Hydrogen/Helium Separator

- Hydrogen and helium, due to their small molecular sizes and similar physical properties, are challenging to separate

- However, by combining palladium membranes with Pressure Swing Adsorption (PSA), 99.999% purity for each gas can be achieved

Main Applications

| Field | Use Case |

|---|---|

| Semiconductor Manufacturing | Situations requiring high-purity hydrogen and helium |

| Bioanalysis | Processes demanding precise gas separation |

| Aerospace Industry | Helium applications in rocket fuel and cryogenic cooling |

| Energy Industry | Used in natural gas and biogas purification |

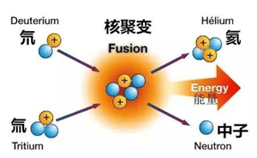

H₂ (Hydrogen) / D₂ (Deuterium) / T₂ (Tritium) Separator

- The separation selectivity of Pd membranes among H₂, D₂, and T₂ is approximately 1.3–2; however, isotopic molecules such as HD, HT, and DT may be generated

- T₂ is primarily produced through nuclear reactions between thermal neutrons and ⁶Li in reactors, and the resulting T₂ and He can be separated using palladium membranes

- T₂ and D₂ fusion reactions have potential applications as sources of clean nuclear energy

Water Electrolysis

- Water electrolysis methods include alkaline electrolysis and PEM membrane-based pure water electrolysis

- General hydrogen generators require drying or catalytic deoxygenation followed by frequent regeneration of drying agents

- Palladium membrane purifiers eliminate the need for drying agents and offer hydrogen purity levels of 6N–8N