ACM / ECS (Air Cycle Machine / Environmental Control System)

Air Cycle Machines (ACMs) are critical for cooling, compressing, and circulating air in aircraft, ensuring a comfortable environment for both cockpit and cabin. NS independently designs and manufactures high-performance ACMs utilizing proprietary technology and advanced engineering expertise.

Key Features

- Maximizes cooling efficiency through high-efficiency compressors, turbines, and optimized heat exchanger design

- Compact, lightweight structure enhances aircraft fuel efficiency

- Maintains stable performance under extreme altitude and temperature conditions

- Capable of meeting diverse specifications and system requirements based on customer needs

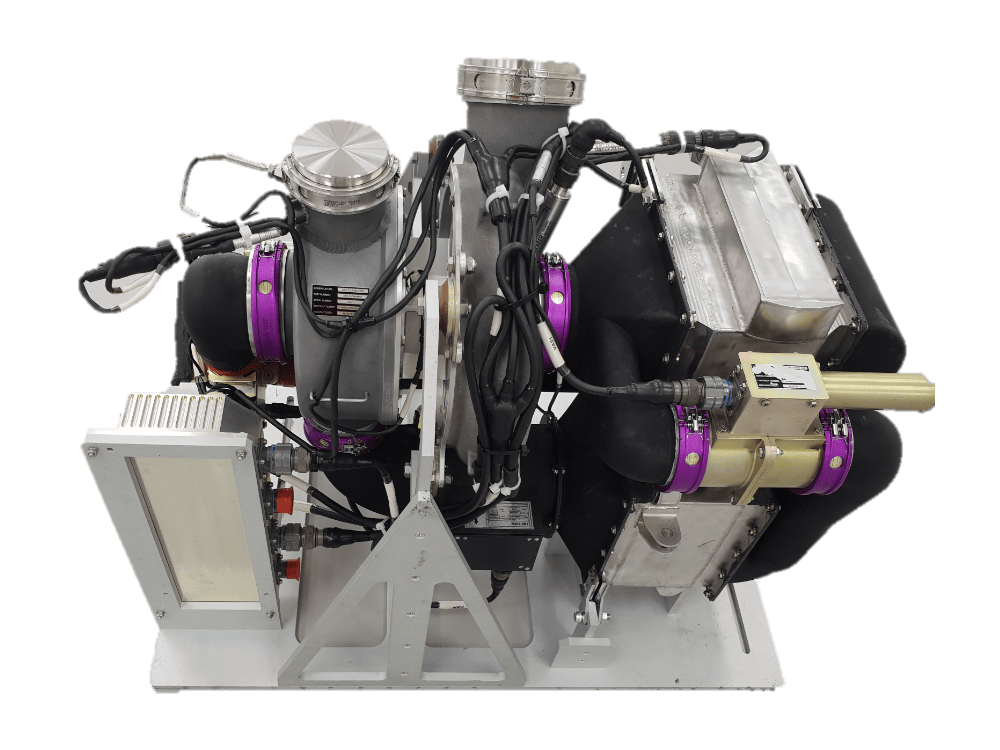

F-16 POD ACM

| Item | Specification | |

|---|---|---|

| Compression Ratio | 1.4 | – |

| Expansion Ratio | 2.0 | – |

| Rotational Speed | 40,000 ~ 60,000 | RPM |

| Dimensions | 250 X 230 | (D x L, mm) |

T-50 ACM

| Item | Specification | |

|---|---|---|

| Compression Ratio | 1.5 | – |

| Expansion Ratio | 6.5 | – |

| Rotational Speed | 70,000 ~ 80,000 | RPM |

| Dimensions | 228 X 400 | (D x L, mm) |

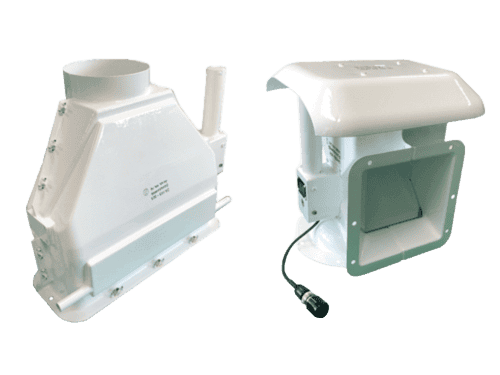

F-16 POD ECS

| Item | Specification | |

|---|---|---|

| Compression Ratio | 1.4 | – |

| Expansion Ratio | 2.0 | – |

| Cooling Capacity | 5kW | |

| Rotational Speed | 40,000 ~ 60,000 | RPM |

| Dimensions | 1000 X 600 X 600 | (LxWxH, mm) |

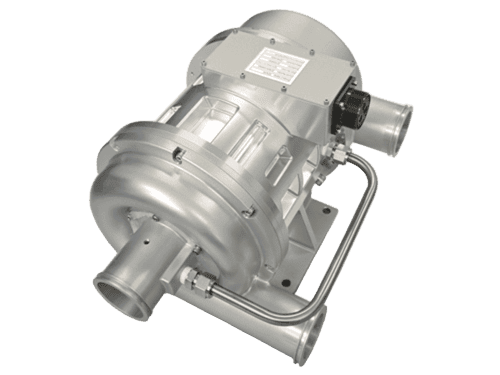

Ground Based ACM

| Item | Specification | |

|---|---|---|

| Rated Power | 25.4 | kW |

| Rated Flowrate | 250 | g/s |

| Discharge Pressure | 150 | kPa(abs) |

| Power Supply | 380 ~ 480 | VDC |

| Dimensions | 473 X 305 X 250 | (LxWxH, mm) |

Notable Applications

- Supplied external POD-type ACMs for F-16 aircraft to the Air Force

- Developed and supplied internal ACMs for the T-50 aircraft

- Exported external POD-type ECS systems for F-16 aircraft to international clients

- Supplied ground-based ACM systems to overseas markets

Heating and Ventilation Units

NS’s aircraft heating and ventilation units feature a blower that draws in outside air and a valve system that precisely controls airflow direction- regulating both volume and flow for optimal cabin conditions.

Key Features

- Provides ventilation, heating, and windshield demisting functions

- Supplies required airflow with optimized axial impellers and two-stage speed control

- Precision flap control through electric valve actuation

Blowers

| Item | Specification | |

|---|---|---|

| Rated Power | 0.896 | W |

| Rated Flowrate | 200 | LPM |

| Discharge Pressure | 1,870 | Pa(g) |

| Rotational Speed | High – 15,100 Low – 9,600 | rpm |

Flapper Valve

| Item | Specification | |

|---|---|---|

| Control Method | Electric control | – |

| Operating Voltage | 28 | VDC |

| Power Consumption | 10 | W |

| Operating Modes | 2 Stage | – |

Notable Applications

- Completed development and delivery of the LAH/LCH systems from 2016 to 2022

- Delivered the first volume production run for the LAH program between 2022 and 2024

- Currently supplying the second mass production phase for the LAH program (since 2024)